Common Production Process of Chip Resistors

I. Introduction

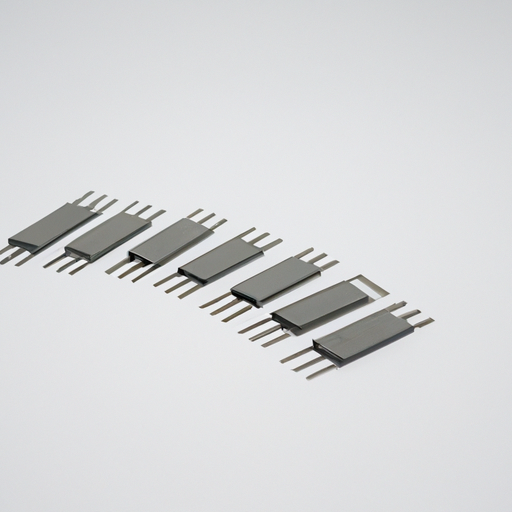

In the realm of modern electronics, chip resistors play a pivotal role in ensuring the proper functioning of various devices. These tiny components, often no larger than a grain of rice, are essential for regulating current flow and voltage levels in circuits. Their compact size, reliability, and precision make them indispensable in applications ranging from consumer electronics to industrial machinery. Understanding the production process of chip resistors not only sheds light on their significance but also highlights the intricate technology involved in their manufacturing.

II. Materials Used in Chip Resistor Production

The production of chip resistors involves a variety of materials, each selected for its unique properties that contribute to the overall performance of the resistor.

A. Substrate Materials

The substrate serves as the foundational layer for the resistor, providing structural support and electrical insulation. The most common substrate materials include:

1. **Ceramic**: Renowned for its excellent thermal stability and electrical insulation properties, ceramic substrates are widely used in chip resistor production. They can withstand high temperatures and are resistant to environmental factors, making them ideal for a range of applications.

2. **Glass**: Glass substrates offer high resistance to environmental factors and are often utilized in high-temperature applications. Their durability and stability under varying conditions make them a reliable choice for specialized resistors.

3. **Polymer**: Flexible and lightweight, polymer substrates are increasingly being used in specialized applications, particularly where space and weight are critical considerations. They provide a balance between performance and manufacturability.

B. Resistive Materials

The resistive element is crucial for determining the performance characteristics of the resistor. Common resistive materials include:

1. **Metal Films**: Thin layers of metals, such as nickel or copper, are used for their precise resistance values and stability. Metal film resistors are known for their low noise and high accuracy, making them suitable for precision applications.

2. **Carbon Films**: Carbon-based materials provide good performance at a lower cost, making them suitable for various applications. They are often used in general-purpose resistors where high precision is not as critical.

3. **Thick Film Pastes**: These pastes are applied to the substrate and then cured, allowing for a wide range of resistance values. Thick film resistors are versatile and can be tailored to meet specific application requirements.

C. Protective Coatings

To enhance durability and performance, chip resistors are often coated with protective materials. These coatings shield the resistors from environmental factors such as moisture, dust, and mechanical stress, ensuring long-term reliability.

III. Design and Specifications

Before the production process begins, engineers must determine the design and specifications of the chip resistors. This phase is critical for ensuring that the final product meets the intended application requirements.

A. Determining Resistance Values

The desired resistance value is calculated based on the application requirements, considering factors such as load and voltage. Engineers use complex formulas and simulations to ensure that the resistor will perform as expected in its intended circuit.

B. Tolerance and Temperature Coefficient

Tolerance indicates how much the actual resistance can vary from the specified value, while the temperature coefficient measures how resistance changes with temperature. These specifications are crucial for applications where precision is paramount, as they directly impact the performance of the electronic circuit.

C. Size and Form Factor Considerations

The physical dimensions of the chip resistor are essential for fitting into electronic circuits. Engineers must consider the size and form factor to ensure compatibility with the overall design of the device, influencing both performance and manufacturability.

IV. Production Process Steps

The production of chip resistors involves several key steps, each critical to ensuring quality and performance.

A. Substrate Preparation

1. **Cutting and Shaping Substrates**: Substrates are cut to the desired size and shape, often using precision cutting tools. This step is crucial for ensuring that the resistors fit properly into their intended applications.

2. **Cleaning and Surface Treatment**: The substrates undergo cleaning processes to remove contaminants, ensuring proper adhesion of subsequent layers. Surface treatments may include chemical etching or plasma cleaning to enhance bonding.

B. Application of Resistive Material

1. **Thin Film Deposition**: Techniques such as sputtering and evaporation are used to deposit thin layers of resistive material onto the substrate. These methods allow for precise control over the thickness and uniformity of the resistive layer.

2. **Thick Film Printing**: Screen printing or inkjet printing methods are employed to apply thick film pastes, allowing for greater flexibility in design. This step enables manufacturers to create resistors with varying resistance values and characteristics.

C. Patterning and Etching

1. **Photolithography**: This process involves applying a photoresist layer, exposing it to light, and developing it to create patterns for etching. Photolithography is essential for achieving the fine details required in modern chip resistor designs.

2. **Laser Trimming**: Precision lasers are used to trim the resistive material to achieve the desired resistance value. This step allows for fine-tuning of the resistor's performance, ensuring it meets the specified tolerance levels.

D. Adding Terminals

1. **Soldering Pads**: Metal pads are added to the resistor for electrical connections. These pads are designed to facilitate easy integration into electronic circuits.

2. **Metalization Techniques**: Various methods, such as electroplating, are used to ensure strong and reliable connections. Proper metalization is crucial for maintaining the electrical integrity of the resistor.

E. Curing and Sintering

1. **Thermal Treatment**: The resistive materials are cured at high temperatures to enhance their properties. This step is essential for achieving the desired electrical characteristics and mechanical strength.

2. **Time and Temperature Considerations**: The curing process must be carefully controlled to achieve optimal performance. Variations in time and temperature can significantly impact the final product's quality.

V. Quality Control and Testing

Quality control is a critical aspect of chip resistor production, ensuring that each component meets stringent standards.

A. Electrical Testing

1. **Resistance Measurement**: Automated systems measure the resistance of each chip resistor to verify compliance with specifications. This testing is essential for ensuring that the resistors perform as intended in their applications.

2. **Tolerance Verification**: Each resistor is checked to ensure it falls within the specified tolerance range. This step is crucial for maintaining the reliability of electronic circuits.

B. Environmental Testing

1. **Temperature Cycling**: Resistors undergo temperature cycling tests to assess their performance under varying conditions. This testing simulates real-world conditions and helps identify potential failures.

2. **Humidity Exposure**: Testing for humidity resistance ensures reliability in diverse environments. Resistors must be able to withstand moisture without degrading their performance.

C. Visual Inspection

Visual inspections are conducted to identify any defects or inconsistencies in the manufacturing process. This step helps catch issues early, preventing defective products from reaching customers.

VI. Packaging and Distribution

Once produced and tested, chip resistors are packaged and prepared for distribution.

A. Types of Packaging

1. **Tape and Reel**: This method is commonly used for automated assembly processes, allowing for easy handling and placement. Tape and reel packaging is designed to facilitate efficient manufacturing.

2. **Bulk Packaging**: For larger orders, bulk packaging may be used to reduce costs. This method is often preferred for high-volume applications.

B. Labeling and Documentation

Each package is labeled with essential information, including resistance values, tolerances, and manufacturing dates. Proper labeling is crucial for traceability and quality assurance.

C. Shipping Considerations

Proper shipping methods are employed to ensure that the resistors arrive at their destination in optimal condition. This includes protective packaging to prevent damage during transit.

VII. Conclusion

The production process of chip resistors is a complex and precise operation that involves careful selection of materials, meticulous design, and rigorous testing. As technology advances, the demand for high-quality chip resistors continues to grow, driving innovations in manufacturing techniques and materials. Understanding this process not only highlights the importance of chip resistors in electronic circuits but also underscores the commitment to quality and precision that manufacturers uphold in their production efforts.

Future trends may lead to even more efficient production methods and enhanced performance characteristics, further solidifying the role of chip resistors in the ever-evolving landscape of electronics. As the industry continues to innovate, chip resistors will remain a cornerstone of electronic design, enabling the development of more sophisticated and reliable devices.

Common Production Process of Chip Resistors

I. Introduction

In the realm of modern electronics, chip resistors play a pivotal role in ensuring the proper functioning of various devices. These tiny components, often no larger than a grain of rice, are essential for regulating current flow and voltage levels in circuits. Their compact size, reliability, and precision make them indispensable in applications ranging from consumer electronics to industrial machinery. Understanding the production process of chip resistors not only sheds light on their significance but also highlights the intricate technology involved in their manufacturing.

II. Materials Used in Chip Resistor Production

The production of chip resistors involves a variety of materials, each selected for its unique properties that contribute to the overall performance of the resistor.

A. Substrate Materials

The substrate serves as the foundational layer for the resistor, providing structural support and electrical insulation. The most common substrate materials include:

1. **Ceramic**: Renowned for its excellent thermal stability and electrical insulation properties, ceramic substrates are widely used in chip resistor production. They can withstand high temperatures and are resistant to environmental factors, making them ideal for a range of applications.

2. **Glass**: Glass substrates offer high resistance to environmental factors and are often utilized in high-temperature applications. Their durability and stability under varying conditions make them a reliable choice for specialized resistors.

3. **Polymer**: Flexible and lightweight, polymer substrates are increasingly being used in specialized applications, particularly where space and weight are critical considerations. They provide a balance between performance and manufacturability.

B. Resistive Materials

The resistive element is crucial for determining the performance characteristics of the resistor. Common resistive materials include:

1. **Metal Films**: Thin layers of metals, such as nickel or copper, are used for their precise resistance values and stability. Metal film resistors are known for their low noise and high accuracy, making them suitable for precision applications.

2. **Carbon Films**: Carbon-based materials provide good performance at a lower cost, making them suitable for various applications. They are often used in general-purpose resistors where high precision is not as critical.

3. **Thick Film Pastes**: These pastes are applied to the substrate and then cured, allowing for a wide range of resistance values. Thick film resistors are versatile and can be tailored to meet specific application requirements.

C. Protective Coatings

To enhance durability and performance, chip resistors are often coated with protective materials. These coatings shield the resistors from environmental factors such as moisture, dust, and mechanical stress, ensuring long-term reliability.

III. Design and Specifications

Before the production process begins, engineers must determine the design and specifications of the chip resistors. This phase is critical for ensuring that the final product meets the intended application requirements.

A. Determining Resistance Values

The desired resistance value is calculated based on the application requirements, considering factors such as load and voltage. Engineers use complex formulas and simulations to ensure that the resistor will perform as expected in its intended circuit.

B. Tolerance and Temperature Coefficient

Tolerance indicates how much the actual resistance can vary from the specified value, while the temperature coefficient measures how resistance changes with temperature. These specifications are crucial for applications where precision is paramount, as they directly impact the performance of the electronic circuit.

C. Size and Form Factor Considerations

The physical dimensions of the chip resistor are essential for fitting into electronic circuits. Engineers must consider the size and form factor to ensure compatibility with the overall design of the device, influencing both performance and manufacturability.

IV. Production Process Steps

The production of chip resistors involves several key steps, each critical to ensuring quality and performance.

A. Substrate Preparation

1. **Cutting and Shaping Substrates**: Substrates are cut to the desired size and shape, often using precision cutting tools. This step is crucial for ensuring that the resistors fit properly into their intended applications.

2. **Cleaning and Surface Treatment**: The substrates undergo cleaning processes to remove contaminants, ensuring proper adhesion of subsequent layers. Surface treatments may include chemical etching or plasma cleaning to enhance bonding.

B. Application of Resistive Material

1. **Thin Film Deposition**: Techniques such as sputtering and evaporation are used to deposit thin layers of resistive material onto the substrate. These methods allow for precise control over the thickness and uniformity of the resistive layer.

2. **Thick Film Printing**: Screen printing or inkjet printing methods are employed to apply thick film pastes, allowing for greater flexibility in design. This step enables manufacturers to create resistors with varying resistance values and characteristics.

C. Patterning and Etching

1. **Photolithography**: This process involves applying a photoresist layer, exposing it to light, and developing it to create patterns for etching. Photolithography is essential for achieving the fine details required in modern chip resistor designs.

2. **Laser Trimming**: Precision lasers are used to trim the resistive material to achieve the desired resistance value. This step allows for fine-tuning of the resistor's performance, ensuring it meets the specified tolerance levels.

D. Adding Terminals

1. **Soldering Pads**: Metal pads are added to the resistor for electrical connections. These pads are designed to facilitate easy integration into electronic circuits.

2. **Metalization Techniques**: Various methods, such as electroplating, are used to ensure strong and reliable connections. Proper metalization is crucial for maintaining the electrical integrity of the resistor.

E. Curing and Sintering

1. **Thermal Treatment**: The resistive materials are cured at high temperatures to enhance their properties. This step is essential for achieving the desired electrical characteristics and mechanical strength.

2. **Time and Temperature Considerations**: The curing process must be carefully controlled to achieve optimal performance. Variations in time and temperature can significantly impact the final product's quality.

V. Quality Control and Testing

Quality control is a critical aspect of chip resistor production, ensuring that each component meets stringent standards.

A. Electrical Testing

1. **Resistance Measurement**: Automated systems measure the resistance of each chip resistor to verify compliance with specifications. This testing is essential for ensuring that the resistors perform as intended in their applications.

2. **Tolerance Verification**: Each resistor is checked to ensure it falls within the specified tolerance range. This step is crucial for maintaining the reliability of electronic circuits.

B. Environmental Testing

1. **Temperature Cycling**: Resistors undergo temperature cycling tests to assess their performance under varying conditions. This testing simulates real-world conditions and helps identify potential failures.

2. **Humidity Exposure**: Testing for humidity resistance ensures reliability in diverse environments. Resistors must be able to withstand moisture without degrading their performance.

C. Visual Inspection

Visual inspections are conducted to identify any defects or inconsistencies in the manufacturing process. This step helps catch issues early, preventing defective products from reaching customers.

VI. Packaging and Distribution

Once produced and tested, chip resistors are packaged and prepared for distribution.

A. Types of Packaging

1. **Tape and Reel**: This method is commonly used for automated assembly processes, allowing for easy handling and placement. Tape and reel packaging is designed to facilitate efficient manufacturing.

2. **Bulk Packaging**: For larger orders, bulk packaging may be used to reduce costs. This method is often preferred for high-volume applications.

B. Labeling and Documentation

Each package is labeled with essential information, including resistance values, tolerances, and manufacturing dates. Proper labeling is crucial for traceability and quality assurance.

C. Shipping Considerations

Proper shipping methods are employed to ensure that the resistors arrive at their destination in optimal condition. This includes protective packaging to prevent damage during transit.

VII. Conclusion

The production process of chip resistors is a complex and precise operation that involves careful selection of materials, meticulous design, and rigorous testing. As technology advances, the demand for high-quality chip resistors continues to grow, driving innovations in manufacturing techniques and materials. Understanding this process not only highlights the importance of chip resistors in electronic circuits but also underscores the commitment to quality and precision that manufacturers uphold in their production efforts.

Future trends may lead to even more efficient production methods and enhanced performance characteristics, further solidifying the role of chip resistors in the ever-evolving landscape of electronics. As the industry continues to innovate, chip resistors will remain a cornerstone of electronic design, enabling the development of more sophisticated and reliable devices.